Furnace Top Bottom Block

Product Details:

- Glass Size Customizable as per requirement

- Feature High Strength, Corrosion Resistant, Precision Formed, Long Service Life

- Rating High Thermal Shock Resistance

- Condition New

- Type Furnace Top Bottom Block

- Usage Industrial Furnace lining and support

- Size Standard / Custom as per requirement

- Click to view more

Furnace Top Bottom Block Price And Quantity

- Smooth for Uniform Load Bearing

- White/Grey

- Rectangular, Custom Shapes Available

- Precision Cast and Machined

- Minimal for Structural Integrity

- Low Porosity for Enhanced Durability

- High

- Manual or Mechanical Placement

- Fused Cast AZS, High Alumina or Silica

- ISO/IS Standard for Furnace Blocks

- 2.8-3.4 g/cm³

- Up to 1700°C

Furnace Top Bottom Block Product Specifications

- Furnace Top Bottom Block

- Industrial Furnace lining and support

- High Strength, Corrosion Resistant, Precision Formed, Long Service Life

- Standard / Custom as per requirement

- Customizable as per requirement

- New

- Depends on furnace

- Varies according to size and material

- Varies (as per furnace design)

- Glass Melting Furnace / Industrial Furnace

- High Thermal Shock Resistance

- Compatible with Gas, Oil, Electric Furnace

- Smooth for Uniform Load Bearing

- White/Grey

- Rectangular, Custom Shapes Available

- Precision Cast and Machined

- Minimal for Structural Integrity

- Low Porosity for Enhanced Durability

- High

- Manual or Mechanical Placement

- Fused Cast AZS, High Alumina or Silica

- ISO/IS Standard for Furnace Blocks

- 2.8-3.4 g/cm³

- Up to 1700°C

Furnace Top Bottom Block Trade Information

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Central America, Asia

- All India

Product Description

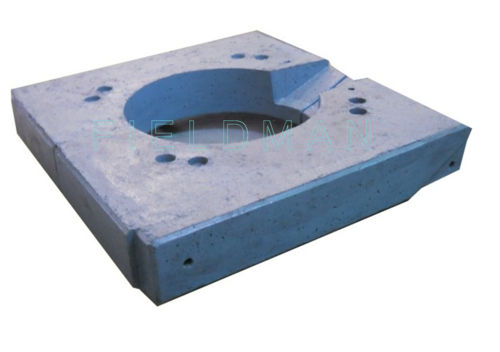

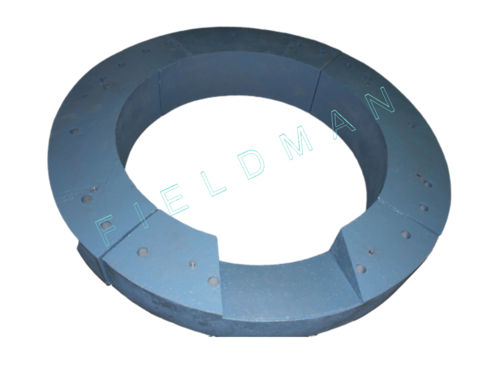

Furnace Top & Bottom Block

We have state of art facility available for Manufacturing Furnace Bottom Block for Induction Furnaces. Our in-house capacity is to manufacture Top & Bottom blocks of 100KG To 10,000 KG.

Refractory castable block for Inductotherm Furnaces, Electrotherm, and other Furnaces are available with us.

We offer a service of developing these items as per customized requirement.

Function:

Main Function of these Top & Bottom Blocks is to hold Induction Coil tightly. Bottom block give the base support to hold the coil and keep in shape while tilting of the furnace.

Top and bottom blocks are tightly stick with aluminum side plates with the help of horizontal Tie Rods.

Optimized Materials for Extreme Durability

Our furnace blocks utilize advanced materials like Fused Cast AZS, High Alumina, and Silica to deliver exceptional resistance to high temperatures, abrasion, and corrosion. Their low porosity enhances both durability and resistance to chemical attack, offering extended service life and reducing maintenance frequency.

Precision Manufacturing for Superior Performance

Every block is precision cast and machined to meet stringent international (ISO/IS) standards. The smooth surface finish ensures uniform load-bearing and minimizes stress points, while minimal thermal expansion preserves structural integrity even under severe thermal cycling, making them ideal for industrial furnace lining and support.

Customizable Solutions for Industrial Furnaces

We offer a range of standard sizes and custom shapes tailored to specific furnace designs. Depending on your application, our team assists in selecting the appropriate material and configuration for optimal performance, ensuring compatibility with gas, oil, or electric furnaces used in glass melting and related industries.

FAQs of Furnace Top Bottom Block:

Q: How are Furnace Top Bottom Blocks installed in industrial furnaces?

A: Furnace Top Bottom Blocks can be installed manually or using mechanical placement tools, depending on the size, weight, and design of the furnace. Installation processes are guided by precision fit and proper alignment to ensure uniform load distribution and structural stability.Q: What materials are available for these furnace blocks and how do I select the right one?

A: The blocks are available in Fused Cast AZS, High Alumina, and Silica. Selection depends on your specific furnace conditions such as temperature, chemical exposure, and load requirements. Our technical team can help assess your needs and recommend the best material solution.Q: When should I choose a custom-shaped furnace block over a standard one?

A: Custom-shaped blocks are advised when your furnace design involves unique geometries, dimensions, or requires tailored features for improved efficiency or compatibility. We offer design support to ensure a precise fit for your specialized application.Q: Where are these furnace blocks typically used?

A: These blocks are primarily used in industrial furnaces, especially glass melting furnaces, as lining and support components. Their robust construction and high resistance make them suitable for environments requiring exceptional durability under intense operational conditions.Q: What benefits do low-porosity and high-density features offer?

A: Low porosity and high density enhance abrasion and corrosion resistance, reduce the risk of chemical infiltration, and prolong the service life of the block. This leads to less downtime, lower maintenance costs, and increased reliability.Q: How does the manufacturing process ensure quality and compliance?

A: The blocks are produced through precision casting and machining, with each piece meeting ISO/IS standards. Rigorous quality checks are performed to guarantee consistency in dimensions, surface finish, and performance, ensuring they meet industrial requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+