Thyristors For Induction Furnaces

Product Details:

- Product Type Thyristors For Induction Furnaces

- Application Power control and switching in induction heating and melting furnaces

- Supply Voltage Up to 1200V

- Dissipation Power High efficiency, low dissipation

- Operating Temperature -40C to +125C

- Power Consumption Low

- Temperature Range -40C to +125C

- Click to view more

X

Thyristors For Induction Furnaces Product Specifications

- Customized/standard module sizes available

- Phase-controlled

- Low

- Up to 1200V

- 400V 1200V

- High efficiency, low dissipation

- Depends on module, approx. 150g 500g

- Power control and switching in induction heating and melting furnaces

- -40C to +125C

- -40C to +125C

- Thyristors For Induction Furnaces

Thyristors For Induction Furnaces Trade Information

- Western Europe, Australia, North America, South America, Eastern Europe, Middle East, Central America, Asia, Africa

- All India

Product Description

Thyristors For Induction Furnaces

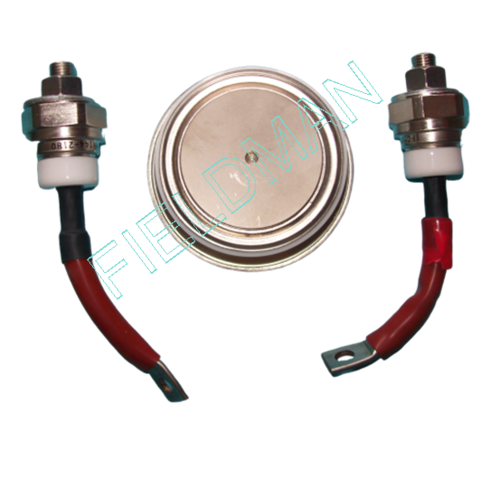

We are manufacture and supply Disc thyristor clamp assembly of various size of thyristor devices.

We design and manufacture Assembly as per required pressure to be applied for proper operating of the device. Chill blocks which are use in the assembly are design from high conductive silver plated copper to provide efficient cooling of the device.

Versatility for Heavy-Duty Industrial Environments

Our thyristors excel in electric arc furnaces, steel plant induction systems, and foundries due to their high current rating and superior surge current capability. With flexible package optionsstud or modulethey seamlessly fit both new setups and retrofits, ensuring dependable performance for continuous or heavy-duty cycles.

Advanced Electrical Protection and Efficiency

Integrated reverse voltage protection safeguards sensitive equipment, while phase-controlled voltage regulation stabilizes supply voltages from 400V to 1200V. Their high isolation voltage and low gate trigger requirements allow efficient power controlwith lower power consumption and heat dissipationwithin rigorous safety standards.

FAQs of Thyristors For Induction Furnaces:

Q: How are these thyristors mounted in induction furnace systems?

A: These thyristors support both panel and chassis mounting, giving you flexibility for integration into various industrial setups, whether upgrading existing equipment or installing new systems.Q: What makes these thyristors suitable for heavy-duty cycles in steel and foundry environments?

A: Their high current ratings (300A to 2500A), strong surge current capability, and ability to withstand wide temperature ranges (-40C to +125C operating, -40C to +150C storage) make them robust performers for demanding duty cycles typical in electric arc furnaces and induction heating.Q: When should I choose stud versus module type packages for thyristor installation?

A: Stud-type packages are best for compact spaces or direct bolt-down mounting, while module types are suitable for panel installations and higher power applications, offering greater flexibility in system design.Q: Where are these thyristors commonly used, and what are their typical applications?

A: They are widely used in steel plants, induction furnaces, foundries, and industrial power converters for power control, switching, and voltage regulation in heating or melting processes.Q: What benefits do the reverse voltage protection and high isolation voltage features provide?

A: Reverse voltage protection prevents equipment damage from voltage spikes, and high isolation voltage (2500V RMS minimum) ensures safe operation by minimizing the risk of electrical faults or short circuits, protecting both the thyristor and connected systems.Q: What efficiency advantages do these thyristors offer for industrial power control?

A: They deliver high efficiency and low dissipation power control, helping reduce energy costs, minimize heat build-up, and prolong system service life. Their RoHS compliance further ensures eco-friendly and safe manufacturing practices.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email