Fast Acting Fuse for Induction Furnaces

Product Details:

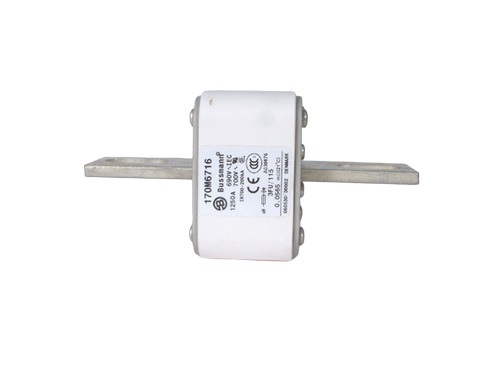

- Product Type Fast Acting Fuse

- Application Induction Furnaces

- Supply Voltage 415 V AC

- Dissipation Power Low

- Operating Temperature -40C to +85C

- Power Consumption Minimal, as per fuse rating

- Temperature Range -40C to +85C

- Click to view more

X

Fast Acting Fuse for Induction Furnaces Product Specifications

- Low

- Approx. 100-350 grams, depending on size

- Minimal, as per fuse rating

- 415 V AC

- -40C to +85C

- 415 V AC

- -40C to +85C

- Standard and Custom sizes available (refer to model)

- Fast Acting Fuse

- Induction Furnaces

- IS/IEC 60269-1 & 2, CE Marked

- Copper with Silver Plating

- High Grade Ceramic / Fiber Glass Body

- High; typically up to 80 kA

- Silicon Sand filled

- Varies from 10A to 800A

- Blade Contacts / Bolted

- White / Off-White

- Non-resettable one time use

- Bolt Type (DIN / Knife Blade)

- RoHS Compliant

- Ultra-Fast (<1 ms)

- > 1000 M at 500V DC

Fast Acting Fuse for Induction Furnaces Trade Information

- Western Europe, Australia, North America, Eastern Europe, Africa, Central America, Middle East, South America, Asia

- All India

Product Description

We are supplying Semiconductor Fast Acting fuse for Induction Heating and Melting Furnace power supply unit. Fast acting fuse are used to protect converter device from high input current surge and fuse are selected as per required I2t curve.

Various rating of Fast Acting Fuse like 300A,500A, 800A, 900A, 1000A, 1250A, 1500A and 1600A are available in stocks.

Ultra-Reliable Protection for Induction Furnaces

This fuse guarantees excellent protection for induction furnace operations, responding instantly to overcurrent events. Its high breaking capacity and superior insulation prevent electrical hazards and maintain operational safety. The ceramic or fiberglass body ensures mechanical strength and longevity, while compliance with multiple international standards reinforces its dependability in industrial environments.

Designed for Seamless Integration

With bolt type (DIN/Knife Blade) mounting and blade contact end connections, installation is straightforward and secure. The fuse suits both standard and custom dimensions, accommodating diverse furnace configurations. Minimal power dissipation and low weight (100-350 grams) further enhance adaptability and efficiency in demanding settings.

FAQs of Fast Acting Fuse for Induction Furnaces:

Q: How does the fast acting fuse protect induction furnaces during electrical faults?

A: The fuse provides ultra-fast response, disconnecting the circuit in less than 1 millisecond during overcurrent or short-circuit events. Its high breaking capacity (up to 80 kA) ensures the safe interruption of electrical faults, preventing damage to sensitive furnace components.Q: What standards and certifications does this fuse comply with?

A: This fuse meets IS/IEC 60269-1 & 2 requirements, carries CE marking for European safety compliance, and is RoHS compliant, ensuring rigorous environmental and operational standards.Q: When should the fuse be replaced in an induction furnace?

A: Replacement is necessary after a fault has occurred, as the fuse is non-resettable and designed for single-use operation. Always use a fuse with the correct current rating for your application.Q: Where can this fuse be installed within an induction furnace system?

A: The fuse is installed at critical points in the furnaces electrical circuit, usually at main incoming power lines or feeder circuits, using bolt type (DIN or knife blade) mounting for secure fixation.Q: What benefits does using a silicon sand-filled fuse offer?

A: The silicon sand filling efficiently quenches arcs during fault conditions, minimizing energy dissipation and enhancing safety by preventing electrical fire risks and component damage.Q: How do I choose the appropriate fuse rating for my induction furnace?

A: Select a fuse rating that matches the current requirements of your furnace (10A to 800A available). Refer to the furnace manufacturers specifications and consider both operating current and potential fault currents for optimal protection.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email