Furance Bottom Cast

Product Details:

- Rating Industrial Grade

- Feature High temperature resistance, Robust construction

- Condition New

- Type Furnace Bottom Cast

- Usage Industrial Melting Furnace

- Size Custom as per requirement

- Dimensions Standard/Custom

- Click to view more

X

Furance Bottom Cast Price And Quantity

- Custom mounting holes/slots available

- 5-7 Years (depending on usage)

- Shot blasted, rust-resistant coating

- As per requirement

- Low

- Wooden crate packing for safe transit

- ±1 mm

- Up to 1600°C

- Minimal, periodic inspection recommended

- High Strength Cast Iron / Alloy Cast

- Excellent with protective coating

- Sand casting, Precision machined

Furance Bottom Cast Product Specifications

- Industrial Melting Furnace

- High temperature resistance, Robust construction

- Bottom structure support in furnace

- Custom as per design

- New

- Custom as per requirement

- Varies with furnace size

- Electric/Oil/Gas

- Furnace Bottom Cast

- Standard/Custom

- Industrial Grade

- Custom mounting holes/slots available

- 5-7 Years (depending on usage)

- Shot blasted, rust-resistant coating

- As per requirement

- Low

- Wooden crate packing for safe transit

- ±1 mm

- Up to 1600°C

- Minimal, periodic inspection recommended

- High Strength Cast Iron / Alloy Cast

- Excellent with protective coating

- Sand casting, Precision machined

Furance Bottom Cast Trade Information

- Western Europe, Australia, Eastern Europe, Middle East, Central America, South America, Asia, North America, Africa

- All India

Product Description

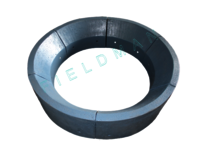

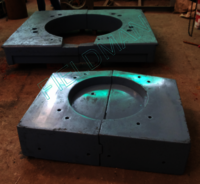

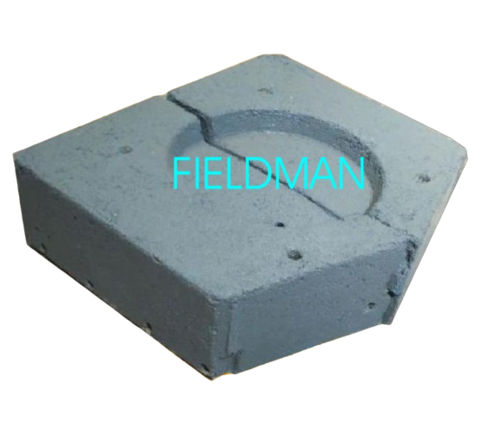

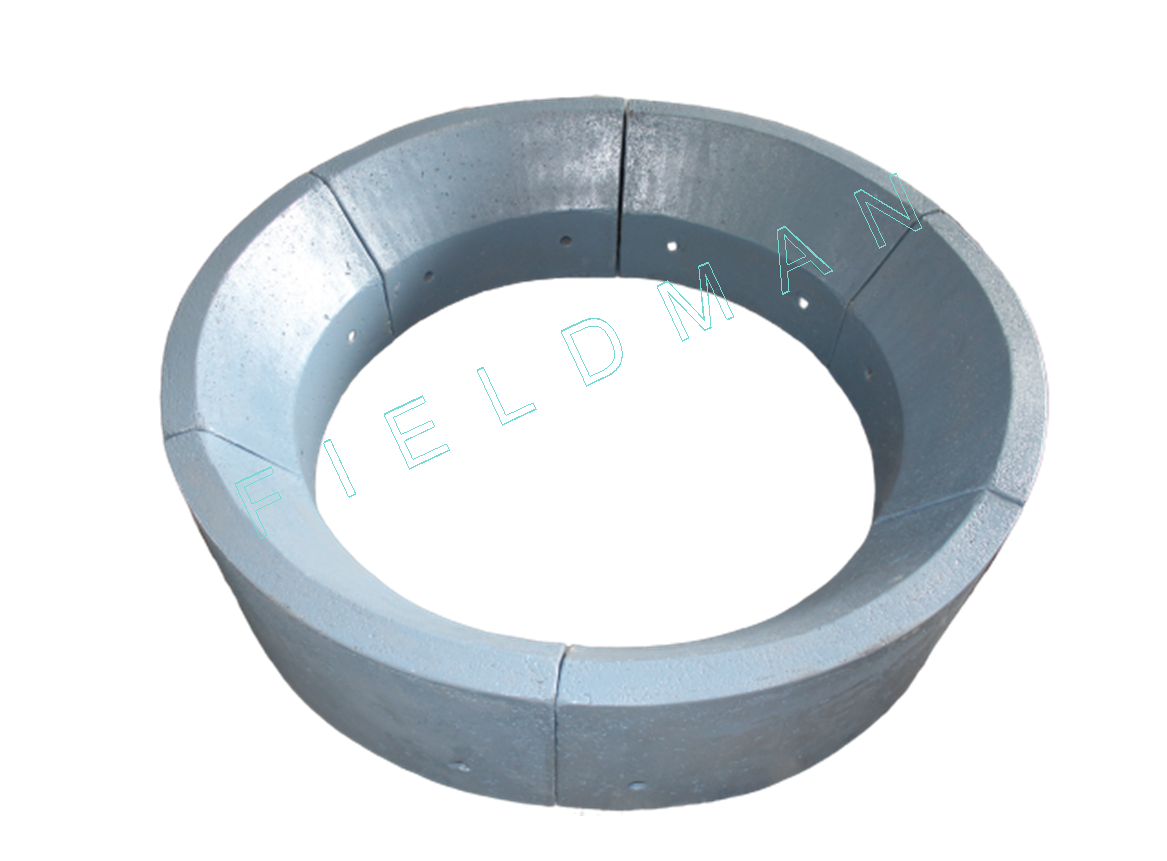

Furance Bottom Cast

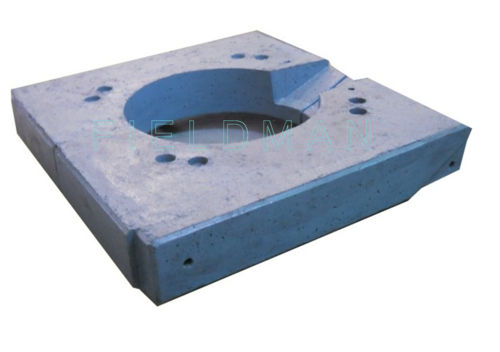

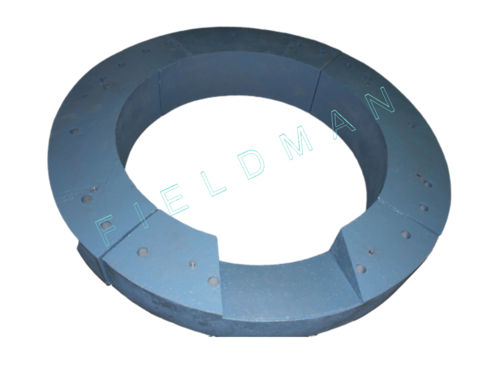

We are counted among some of the most trusted manufacturer and exporter of a wide gamut of Furnace Bottom cast. These are designed and manufactured as power industry laid norms and guidelines. These are manufactured under the strict supervision of our adept manpower who leave no stones unturned when it comes to maintain optimum level of quality. Our range of Furnace Bottom cast is best acknowledged for attributes like high rigidity, elegant shape, superior resistance to thermal condition, excellent performance, etc.

Superior Material and Construction

Manufactured from high-strength cast iron or alloy cast, the Furnace Bottom Cast leverages advanced sand casting and precision machining techniques. This ensures structural integrity and longevity even in intense thermal environments, providing robust support for industrial melting furnaces.

Customizable Features and Mounting Options

To meet diverse operational needs, the Furnace Bottom Cast offers customization in size, color, and mounting options. Custom mounting holes and slots can be specified for compatibility, ensuring adaptability across various furnace designs and applications.

Reliable Performance and Durable Protection

With a high tolerance of 1 mm and a rust-resistant coating, this product is engineered for minimal maintenance and maximum operational reliability. Its corrosion-resistant properties and packaging in wooden crates guarantee safe delivery and sustained performance even in challenging conditions.

FAQs of Furance Bottom Cast:

Q: How is the Furnace Bottom Cast manufactured?

A: The Furnace Bottom Cast is produced using sand casting followed by precision machining. This process delivers both structural strength and precise dimensional tolerances suitable for industrial melting furnaces.Q: What makes the Furnace Bottom Cast suitable for high-temperature operations?

A: It is constructed from high-strength cast iron or alloy cast, designed to withstand temperatures up to 1600C. The component features low heat conductivity and robust construction to perform reliably in intense thermal environments.Q: When should I perform maintenance on the Furnace Bottom Cast?

A: Minimal maintenance is required. However, periodic inspections are recommended to monitor the protective coating and structural integrity, especially in continuous or heavy-use settings.Q: Where is the Furnace Bottom Cast most effectively used?

A: This component is primarily utilized in industrial melting furnaces, serving as the structural bottom support for furnaces operated with electric, oil, or gas fuels.Q: What mounting options are available for Furnace Bottom Cast?

A: Custom mounting holes and slots can be requested to accommodate different furnace designs, ensuring a secure and adaptable installation.Q: What are the benefits of the protective rust-resistant coating?

A: The rust-resistant coating enhances corrosion resistance, prolonging the casts lifespan and maintaining performance in harsh industrial environments.Q: How is the Furnace Bottom Cast packaged for delivery?

A: Each product is packed in sturdy wooden crates to prevent damage during transit, ensuring it arrives in optimal condition for immediate installation.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email