Induction Furnace Top Block

Product Details:

- Feature High thermal resistance, Precision crafted, Durable under high temperatures

- Rating Up to 3500 kW

- Condition New

- Type Top Block for Induction Furnace

- Usage Used as an insulating and supporting block at the top of induction furnaces

- Power Compatible with furnace operating power

- Voltage Suitable for furnace voltage range: 415 V - 1100 V

- Click to view more

Induction Furnace Top Block Price And Quantity

- 1 Piece

- > 60 MPa

- High alumina refractory castable

- Manual placement or cast-in-situ

- Rectangular/Customized

- Smooth

- 2.5 - 2.7 g/cm³

- Light grey

- 1200°C - 1600°C

- Up to 1600°C

- Wooden Pallet/Box

- Approx. 12-18 months depending on operations

- Low

- Low, <2%

Induction Furnace Top Block Product Specifications

- Electric

- Suitable for furnace voltage range: 415 V - 1100 V

- Used as an insulating and supporting block at the top of induction furnaces

- Supports furnace capacity up to 20 Tons

- Top Block for Induction Furnace

- Induction Melting Furnace

- Customizable as per furnace design

- Compatible with furnace operating power

- New

- Up to 3500 kW

- Standard and customized sizes available

- Depends on customized design and size (nominal 15-50 kg)

- High thermal resistance, Precision crafted, Durable under high temperatures

- > 60 MPa

- High alumina refractory castable

- Manual placement or cast-in-situ

- Rectangular/Customized

- Smooth

- 2.5 - 2.7 g/cm³

- Light grey

- 1200°C - 1600°C

- Up to 1600°C

- Wooden Pallet/Box

- Approx. 12-18 months depending on operations

- Low

- Low, <2%

Induction Furnace Top Block Trade Information

- Cash Advance (CA)

- 10 Piece Per Day

- 1 Days

- Australia, South America, Eastern Europe, Western Europe, Middle East, Central America, Africa, Asia, North America

- All India

Product Description

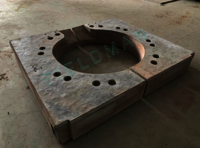

Induction Furnace Top Block

We have state of art facility available for Manufacturing Refractory Top & Bottom Blocks for Induction Furnaces. Our in-house capacity is to manufacture Top & Bottom blocks of 100KG To 10,000 KG.

Refractory castable block for Inductotherm Furnaces, Electrotherm, and other Furnaces are available with us.

We offer a service of developing these items as per customized requirement.

Function:

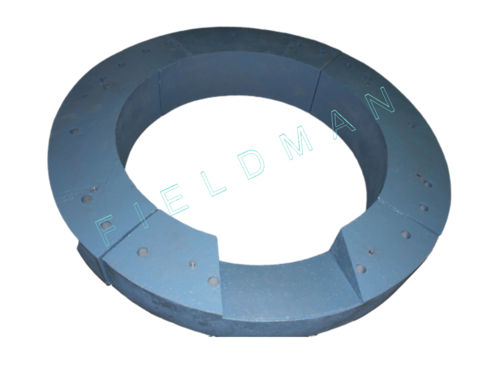

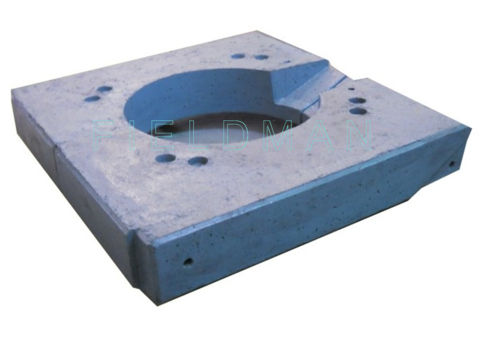

Main Function of these Top & Bottom Blocks is to hold Induction Coil tightly. Bottom block give the base support to hold the coil and keep in shape while tilting of the furnace.

Top and bottom blocks are tightly stick with aluminum side plates with the help of horizontal Tie Rods.

Superior Performance at High Temperatures

Engineered for demanding induction furnace environments, this top block delivers optimal thermal resistance and durability. Its high alumina composition and smooth surface finish ensure minimal maintenance and sustained performance even under continuous exposure to intense heat, making it the preferred choice for heavy-duty melting operations.

Customizable to Fit Your Furnace Design

Available in both rectangular and bespoke shapes, the Induction Furnace Top Block can be tailored to suit specific furnace layouts. Customization options extend to size and weight (1550 kg nominal), delivering seamless integration and enhanced operational efficiency for furnace capacities up to 20 tons.

Precision Installation with Flexible Methods

Installation of the top block is straightforward, whether placed manually or cast in situ per project requirements. This flexibility, combined with low water absorption and a robust design, reduces installation times and enhances the structural reliability of the furnace top section.

FAQs of Induction Furnace Top Block:

Q: What is the main function of the Induction Furnace Top Block?

A: The Induction Furnace Top Block serves as both an insulating and supporting component for the upper section of induction melting furnaces, helping maintain temperature and structural integrity during high-temperature operations.Q: How is the Induction Furnace Top Block installed?

A: It can be installed either through manual placement or by casting in situ, depending on furnace requirements and project specifications, allowing for efficient and precise installation.Q: When should the top block be replaced?

A: Generally, the top block offers a life span of approximately 1218 months, though actual longevity may vary based on furnace usage intensity and maintenance practices.Q: What are the benefits of using high alumina refractory castable in the top block?

A: High alumina refractory castable provides excellent thermal resistance, low water absorption, and superior mechanical strength, ensuring durability and stability at operating temperatures up to 1600C.Q: Where is this top block manufactured and supplied from?

A: As an exporter, manufacturer, and supplier based in India, the product is available for domestic use and international export, with packing options including wooden pallets and boxes for secure shipment.Q: What customization options are available for the top block?

A: The block is available in customized sizes, weights, and shapes to match diverse furnace designs and capacity requirements, ensuring optimal compatibility and performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+