Iron Melting Furnace Assembly

90000 INR/Piece

Product Details:

- Rating High Efficiency

- Feature High Thermal Efficiency, Durable Construction, User Friendly Controls

- Condition New

- Type Iron Melting Furnace Assembly

- Usage Industrial/Foundry

- Power 75 kW - 500 kW

- Voltage 380V/415V

- Click to view more

X

Iron Melting Furnace Assembly Price And Quantity

- 90000 INR/Piece

- 10000 Piece

- <85 dB

- Up to 1.5 MT/hr

- High Alumina Bricks/Refractory Lining

- Mild Steel/Alloy Steel/Insulated Refractories

- Digital/PLC-based Panel

- Water Cooled Lining

- 50 Hz / 60 Hz

- Overheat Protection, Emergency Stop

- Paint Coated/Anti-corrosive

- 1700°C

- On-site Installation Available

- Three Phase

- Semi-Automatic/Automatic

Iron Melting Furnace Assembly Product Specifications

- Industrial/Foundry

- 100 kg - 2000 kg

- Iron Melting, Metal Casting

- Variable as Per Configuration

- 380V/415V

- Electric/Induction

- Standard / Customizable

- As Per Model

- High Efficiency

- Iron Melting Furnace Assembly

- 75 kW - 500 kW

- New

- High Thermal Efficiency, Durable Construction, User Friendly Controls

- <85 dB

- Up to 1.5 MT/hr

- High Alumina Bricks/Refractory Lining

- Mild Steel/Alloy Steel/Insulated Refractories

- Digital/PLC-based Panel

- Water Cooled Lining

- 50 Hz / 60 Hz

- Overheat Protection, Emergency Stop

- Paint Coated/Anti-corrosive

- 1700°C

- On-site Installation Available

- Three Phase

- Semi-Automatic/Automatic

Iron Melting Furnace Assembly Trade Information

- Cash Advance (CA), Cash in Advance (CID), Cheque

- Western Europe, Australia, North America, Eastern Europe, Middle East, Central America, South America, Asia, Africa

- All India

Product Description

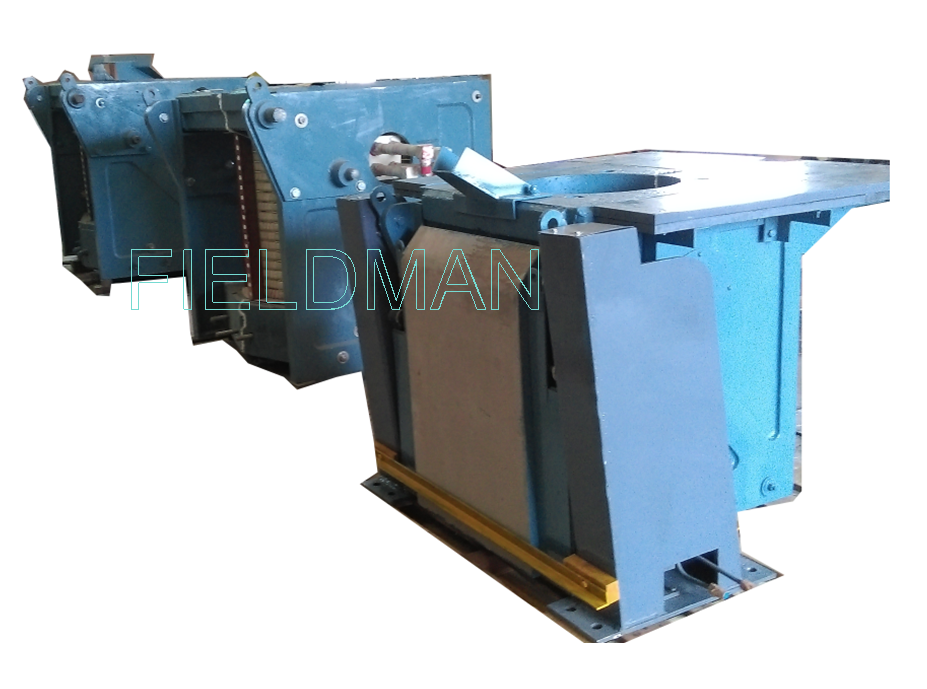

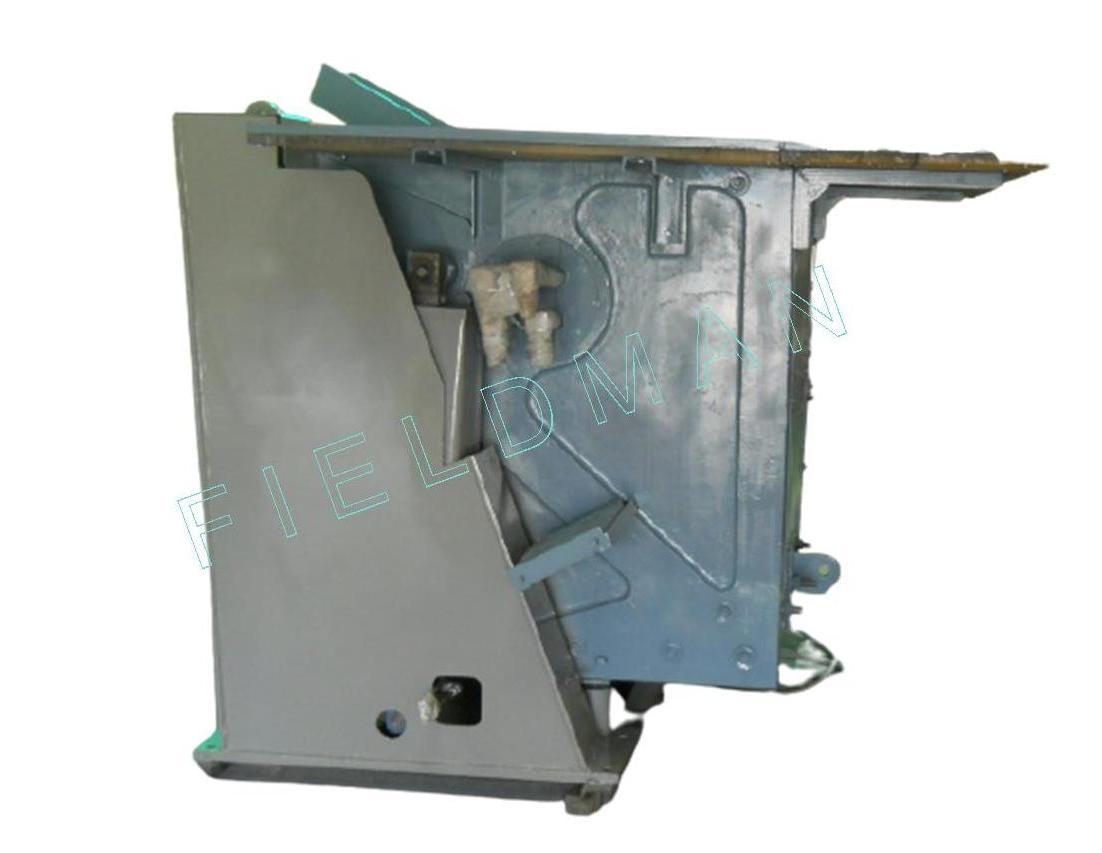

Fieldman Induction has available complete range of Induction Furnace Spares. Our induction melting furnace assembly offers high operational efficiencies with a wide choice of capacities. This is budgetary solution for any melting application.

Features of Iron Melting Furnace Assembly:

- High- strength due to its structured created by reinforced refractory top and bottom blocks, which is supported by SS rods and with firm coil supports.

- Free magnetic path within the furnace provided Maximum efficiency.

- Free breathing coil provides easy maintenance.

- Standard Hoist tilt and hydraulic tilt is available

We have facility to manufacture Induction melting furnace assemblies of the range starting from 100KG to 10,000KG.

Exceptional Melting Efficiency

Engineered to deliver high thermal efficiency, this iron melting furnace assembly achieves melting rates of up to 1.5 metric tons per hour. Its water-cooled lining and high alumina brick insulation ensure stable operations even at intense temperatures, making it a reliable choice for high-output foundry processes.

Advanced Automation & Controls

Featuring a selection of semi-automatic or fully automatic modes, the furnace integrates digital or PLC-based control panels for precise management. User-friendly interfaces enhance operational ease, while safety attributes such as overheat protection and emergency stop functions provide peace of mind during every melt cycle.

Customizable for Every Requirement

Available in both standard and tailor-made dimensions, this assembly meets diverse industrial needs. Power options range from 75 kW to 500 kW, with three-phase operation compatible with 380V or 415V supplies. Quality materials and anti-corrosive coating ensure long-lasting durability, making it a versatile choice for both new projects and upgrades.

FAQs of Iron Melting Furnace Assembly:

Q: How is the Iron Melting Furnace Assembly installed and what support is provided on-site?

A: Installation of the Iron Melting Furnace Assembly is carried out on-site by experienced technicians. Comprehensive support is provided, including initial setup, calibration, safety checks, and operator training to ensure smooth and safe integration into your foundry or industrial operation.Q: What materials can the furnace melt, and what insulation does it use for heat retention?

A: This furnace is specialized for melting iron but can also process various alloy steels, thanks to its high operating temperature and robust design. High alumina bricks and refractory linings are used for insulation, maximizing heat retention and energy efficiency.Q: When should routine maintenance be performed on this furnace?

A: Routine maintenance should be performed as recommended in the user manual, typically after every major melting cycle or as per your operational intensity. Regular checks help preserve the water-cooled lining, control systems, and refractory insulation, ensuring consistent performance and safety.Q: Where can this furnace assembly be utilized, and for what applications?

A: The Iron Melting Furnace Assembly is ideal for industrial environments such as foundries and metal casting units. Its adaptable design supports various sizes and melting capacities, making it suitable for both small-scale and high-volume casting applications.Q: What is the process for controlling and monitoring furnace operations?

A: Operations are managed through an advanced digital or PLC-based control panel, offering straightforward and reliable control of melting processes. Temperature, melt rate, and safety systems can be closely monitored and adjusted as needed, ensuring efficient and precise melting cycles.Q: How does the furnace ensure operator safety during operation?

A: This assembly is equipped with multiple safety features, including an overheat protection system, emergency stop mechanisms, and insulated refractory linings. These measures help prevent accidents, making it safe for continuous use in demanding industrial settings.Q: What are the key benefits of using this iron melting furnace assembly?

A: Benefits include high efficiency, rapid melting capability, customizable capacity, durable construction, user-friendly controls, and reliable safety features. Its robust design and efficient cooling ensure long equipment life and reduced operational downtime.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email