Small Induction Melting Furnace - 50 to 300KG

80000 INR/Unit

Product Details:

- Rating Industrial grade

- Feature High efficiency, low maintenance, fast melting

- Condition New

- Type Induction Melting Furnace

- Usage Metal melting (ferrous and non-ferrous)

- Power 20-180 kW

- Voltage 380-415V, 3 Phase

- Click to view more

X

Small Induction Melting Furnace - 50 to 300KG Price And Quantity

- 10000 Unit

- 80000 INR/Unit

Small Induction Melting Furnace - 50 to 300KG Product Specifications

- Industrial grade

- Small (50 to 300 KG)

- Induction Melting Furnace

- 50 to 300 kg

- New

- 20-180 kW

- Depends on model, ranged 200 to 1000 kg

- High efficiency, low maintenance, fast melting

- Electric

- Varies by capacity, typically compact design

- Foundry, Jewelry, Laboratory, Metal casting

- 380-415V, 3 Phase

- Metal melting (ferrous and non-ferrous)

Small Induction Melting Furnace - 50 to 300KG Trade Information

- Cash Advance (CA), Cash in Advance (CID), Cheque

- Australia, North America, Eastern Europe, Middle East, Central America, South America, Asia, Western Europe, Africa

- All India

Product Description

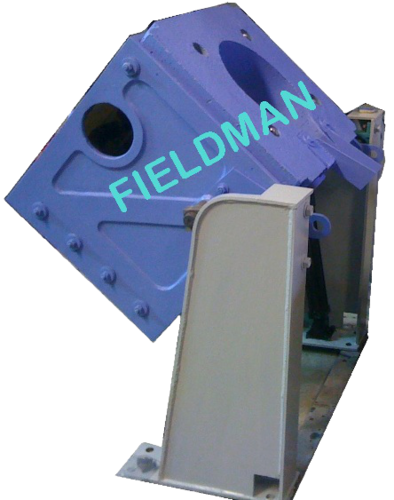

Small Induction Melting Furnace - 50 to 300KG

Fieldman Induction has available complete range of Induction Furnace Spares. Our induction melting furnace assembly offers high operational efficiencies with a wide choice of capacities. This is budgetary solution for any melting application.

We have production capacity of Melting Furnace from 50KG to 15MT Induction furnace crucibles and other spares.

Features of Melting Furnace Assembly:

- High- strength due to its structured created by reinforced refractory top and bottom blocks, which is supported by SS rods and with firm coil supports.

- Free magnetic path within the furnace provided Maximum efficiency.

- Free breathing coil provides easy maintenance.

- Standard Hoist tilt and hydraulic tilt is available

We have facility to manufacture Induction melting furnace assemblies of the range starting from 100KG to 15,000KG.

High-Efficiency Melting Expertise

Combining top-notch engineering with smart digital PLC controls, this induction furnace delivers rapid, energy-saving melting processes for both ferrous and non-ferrous metals. It ensures reliable operations with minimal energy loss, making it ideal for industrial foundries, jewelry workshops, and laboratories alike.

Versatile Crucible Solutions

The furnace supports a variety of crucible materials such as graphite, clay graphite, and silicon carbide, offering flexibility based on metal type and application. Users can easily select the appropriate crucible for optimal melting performance and extended service life.

Smart and Safe Operation

This induction furnace integrates advanced safety features, including overheat protection and emergency stops. Its digital PLC system allows easy monitoring and control, while the closed-circuit water-cooling keeps components running safely even in ambient temperatures up to 40C.

FAQs of Small Induction Melting Furnace - 50 to 300KG:

Q: How does the digital PLC automatic control system benefit furnace operation?

A: The digital PLC automatic control system ensures precise temperature regulation, process monitoring, and easy program management, leading to consistent melting quality and easier operation. It also enhances safety by automating responses to critical situations.Q: What types of metals can this induction melting furnace process?

A: This furnace is suitable for melting a range of ferrous and non-ferrous metals, including steel, iron, copper, aluminum, gold, and silver, making it versatile for foundries, jewelry manufacturing, and laboratories.Q: When should a user choose graphite, clay graphite, or silicon carbide crucibles?

A: Crucible selection depends on the melting temperature, metal type, and desired purity. Graphite is ideal for non-ferrous metals, clay graphite offers durability for longer cycles, and silicon carbide is preferred for corrosive or high-temperature melts.Q: Where is this furnace typically installed and used?

A: Due to its compact size and industrial-grade build, the furnace is suitable for installation in foundries, jewelry workshops, metal casting facilities, and laboratory environments where accurate and efficient melting is required.Q: What is the process for melting metals in this induction furnace?

A: Metal melting involves loading the selected metal and crucible, setting process parameters via the PLC system, initiating the induction heating cycle, and allowing the water-cooled system to manage temperatures until melting is complete in 25-45 minutes.Q: How does the water-cooled, closed-circuit system improve reliability?

A: The closed-circuit water-cooling prevents overheating, protects critical components, extends equipment lifespan, and ensures stable operation even during continuous and high-capacity melting cycles.Q: What are the main benefits of choosing this induction melting furnace for industrial use?

A: Users benefit from high melting efficiency (>95%), rapid batch processing, low maintenance requirements, advanced safety features, and customized options to match specific power and capacity needs.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email