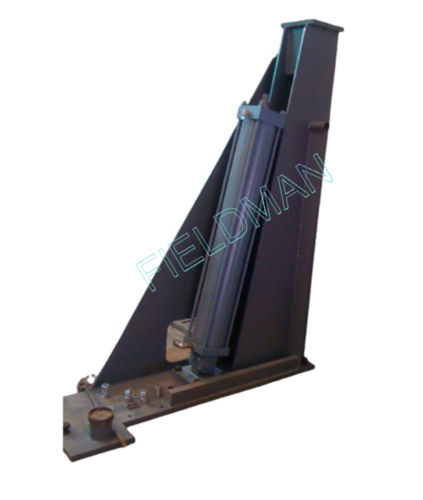

Furnace Stanchion Assembly

25000 INR/Unit

Product Details:

- Glass Size Compatible with Multiple Glass Dimensions

- Feature Corrosion Resistant, Robust Construction, Heat Resistant

- Rating Heavy Duty

- Condition New

- Type Stanchion Assembly

- Usage Furnace Support Structure

- Size Customizable as per furnace design

- Click to view more

X

Furnace Stanchion Assembly Price And Quantity

- 10000 Unit

- 25000 INR/Unit

- Available on Request

- IS, ASTM, or as per Client Specification

- CNC Machined, Fabricated

- 10+ Years (Subject to Use)

- Welded or Bolted, As Per Requirement

- Industrial Grey or as Specified

- Painted / Powder Coated or as Required

- Up to 1500°C

- Mild Steel / Cast Iron / Alloy Steel

- Mounting Plate, Bolts, Washers

Furnace Stanchion Assembly Product Specifications

- High Load Bearing

- Heavy Duty

- Glass Melting Furnace, Industrial Furnace

- New

- Corrosion Resistant, Robust Construction, Heat Resistant

- All Furnace Compatible

- Furnace Support Structure

- Stanchion Assembly

- Depends on Assembly, Typically 40-120 kg

- Standard and As Per Requirement

- Customizable as per furnace design

- Compatible with Multiple Glass Dimensions

- Available on Request

- IS, ASTM, or as per Client Specification

- CNC Machined, Fabricated

- 10+ Years (Subject to Use)

- Welded or Bolted, As Per Requirement

- Industrial Grey or as Specified

- Painted / Powder Coated or as Required

- Up to 1500°C

- Mild Steel / Cast Iron / Alloy Steel

- Mounting Plate, Bolts, Washers

Furnace Stanchion Assembly Trade Information

- Cash Advance (CA), Cash in Advance (CID), Cheque

- Western Europe, Australia, Eastern Europe, Middle East, Central America, South America, Asia, North America, Africa

- All India

Product Description

We are counted among some of the most trusted manufacturers and exporters of a wide gamut ofFurnace Assembly Spares. Our offered furnace assembly parts are engineered industrially using best in class basic material and other components which are procured from some of the most trusted vendors of the industry. Also, before the final delivery, these parts are stringently quality tested to maintain zero defects. In addition to this, our range of Furnace Assembly Spares is highly efficient and suits to varied requirements of clients.

Unmatched Durability and Heat Resistance

Built for demanding environments, our stanchion assemblies endure temperatures up to 1500C while maintaining structural integrity and reliable support. The combination of premium-grade materialsmild steel, cast iron, and alloy steelensures resilience against both mechanical and thermal stress, making them ideal for continuous operation in industrial furnaces.

Precision Engineering and Customization

Each stanchion assembly is CNC machined and fabricated for precise fit and superior performance. Available in a variety of surface finishes, sizes, and installation options, these assemblies can be tailored to meet unique furnace design requirements and client specifications, including color, mounting accessories, and rated capacity.

Comprehensive Compliance and Versatility

Our assemblies adhere to recognized IS and ASTM standards, or may be produced to specific client specifications. Their versatility covers a broad spectrum of furnace types and glass dimensions, supporting high load capacities and integrating seamlessly into new or existing industrial installations.

FAQs of Furnace Stanchion Assembly:

Q: How is the Furnace Stanchion Assembly installed in an industrial furnace?

A: The Furnace Stanchion Assembly is installed either by welding or bolting, based on site requirements and client preferences. Accessories such as mounting plates, bolts, and washers are available to facilitate secure and efficient installation.Q: What materials are used in manufacturing the stanchion assemblies?

A: These assemblies are constructed from high-quality mild steel, cast iron, or alloy steel, selected according to application needs and desired temperature resistance, ensuring compatibility with demanding furnace environments.Q: When should I consider customizing the size or features of the stanchion assembly?

A: Customization is recommended when standard dimensions or specifications do not align with your furnace design, load requirements, or preferred installation method. We accommodate custom requests to suit diverse industrial setups.Q: Where can the Furnace Stanchion Assembly be used?

A: It is suitable for use in glass melting furnaces, industrial furnaces, and any application requiring robust support for furnace structures. The assembly is compatible with all furnace types and multiple glass dimensions.Q: What is the process for manufacturing these assemblies?

A: Manufacturing involves CNC machining and fabrication guided by IS and ASTM standards or specific client requirements. The process ensures precision, optimal fit, and reliable long-term performance under extreme conditions.Q: What are the key benefits of using these stanchion assemblies in your furnace set-up?

A: Key advantages include exceptional thermal resistance up to 1500C, robust construction for heavy load bearing, protection against corrosion, customizable configurations, and service life exceeding 10 years, delivering consistent support and safety.Q: How do I choose the optimal surface finish and color for my furnace stanchion assembly?

A: Surface finishespainted or powder coatedand Industrial Grey or custom colors can be selected based on environmental exposure and aesthetic preference, providing additional protection and alignment with facility standards.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email