Furnace Trunnion Assembly

Product Details:

- Rating Heavy Duty Industrial Grade

- Feature Robust construction, precision machined, low maintenance

- Condition New

- Type Furnace Trunnion Assembly

- Usage Support and rotation of industrial furnace shell

- Power Manual or Motorized as required

- Voltage As per Drive Motor Specification

- Click to view more

Furnace Trunnion Assembly Price And Quantity

- 44000 INR/Unit

- 10000 Unit

Furnace Trunnion Assembly Product Specifications

- Depends on furnace specification (e.g., 500mm-2500mm OD)

- Manual or Motorized as required

- Heavy Duty Industrial Grade

- Customizable as per furnace design

- Robust construction, precision machined, low maintenance

- As per Drive Motor Specification

- Compatible with Gas, Coal, Oil, or Electric Furnaces

- Support and rotation of industrial furnace shell

- Variable (1000 kg to 8000 kg depending on assembly size)

- New

- Cement, Steel, and Metal Processing Industries

- Furnace Trunnion Assembly

- High Load Bearing (Supports up to 500 Tons)

Furnace Trunnion Assembly Trade Information

- Cash Advance (CA), Cash in Advance (CID), Cheque

- Western Europe, Australia, North America, Eastern Europe, Middle East, Africa, Central America, South America, Asia

- All India

Product Description

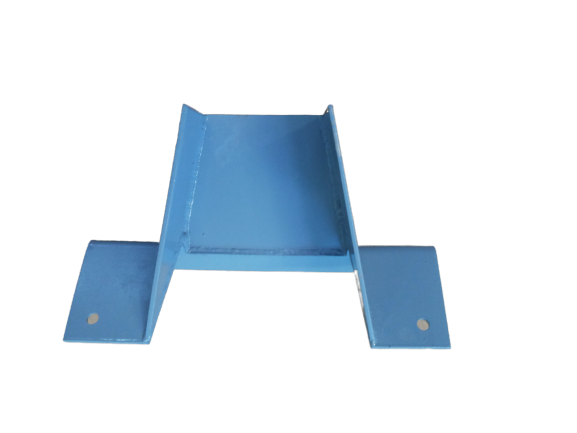

We are manufacturing and supplying Furnace Trunnion Assembly for most of the Induction Melting Duraline furnace of Inductotherm make for 100KG capacity to 10000KG capacity.

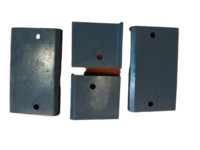

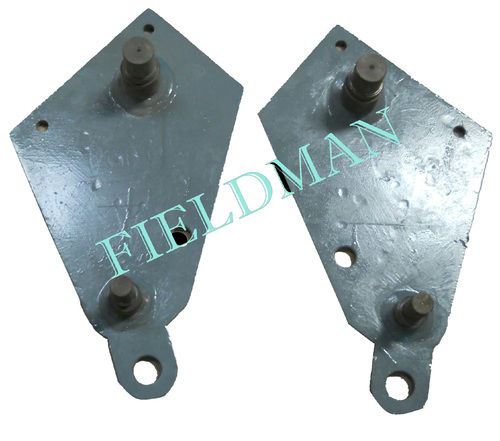

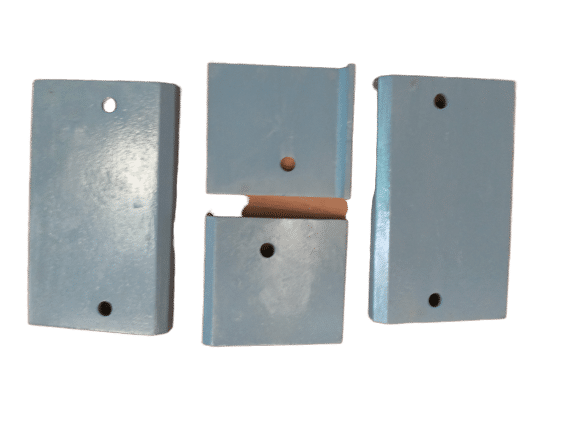

Trunnion Assembly is more important part of Induction Furnace Assembly As the total load of Assembly box is driven with Hydraulic cylinder while tilting and the Induction Melting Furnace box is fitted with cylinder though Trunnion Assembly so it is manufacture from hard Steel materials for better strength.

For its Proper strength and working it is manufactured by profile cutting on CNC machine.

It is fitted with Stanchion bearing through Pivot pin and pivot bearing at one side and on other side joint with hydraulic cylinder with the help of Rod End pin and spherical bearing.

Precision Support and Robust Construction

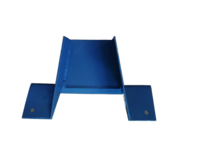

This trunnion assembly features a cast steel or alloy steel body with precision-machined, hardened steel rollers, ensuring stable and reliable support for heavy furnace shells. Its robust frame is designed to withstand continuous high temperatures and heavy industrial loads up to 500 tons, delivering confidence in demanding applications.

Versatile and Customizable Design

Engineered for versatility, the assembly provides adjustable trunnion alignment for precise shell positioning. It is available in multiple mounting configurations, drive arrangements, and custom dimensions (OD 5002500 mm), meeting unique requirements for cement, steel, and metal processing furnaces. Integration options like manual or motorized operations guarantee tailored solutions.

Reliable Performance with Low Maintenance

A centralized or manual greasing system lubricates the heavy-duty roller bearings, supporting low-noise, efficient rotation. The anti-corrosive surface finish enhances durability, while compliance with global standards assures reliability and safety. The assemblys low-maintenance design translates into operational efficiency and reduced downtime.

FAQs of Furnace Trunnion Assembly:

Q: How does the Furnace Trunnion Assembly support industrial furnace operations?

A: The assembly provides stable support and controlled rotation for the furnace shell, using precision-machined, hardened steel rollers mounted on a cast or alloy steel body. This allows heavy shells to rotate smoothly during processing, essential for efficient and continuous operation in industries like cement, steel, and metal processing.Q: What materials are used in the construction of the trunnion assembly, and how does this benefit durability?

A: Manufactured from cast steel or alloy steel with hardened steel rollers, the assembly resists wear and deformation even under high loads and temperatures. An anti-corrosive finish or surface treatment further extends service life by protecting against rust and environmental damage.Q: When should centralized or manual greasing be performed?

A: Lubrication frequency depends on operating intensity and environmental conditions. For continuous operations or high temperatures, centralized greasing can be set to automatically lubricate bearings, while manual greasing should follow a strict maintenance schedule (typically weekly or as per manufacturer recommendations) to prevent wear and ensure smooth movement.Q: Where can Furnace Trunnion Assemblies be installed?

A: These assemblies are suitable for installation in industrial facilities such as cement plants, steel mills, and metal processing units. Their mounting flexibility (base plate or bolt-on) allows adaptation to various furnace structures and designs used in these sectors.Q: What is the customization process for adapting the trunnion assembly to specific requirements?

A: Clients can specify dimensions, mounting type, drive arrangement, and performance features based on their furnace design and operational needs. Manufacturers will review process details and mechanical requirements to deliver a fully customized, heavy-duty assembly that aligns with both global standards and client expectations.Q: How does the assembly ensure low maintenance and operational efficiency?

A: The robust construction, quality roller bearings, centralized or manual lubrication, and anti-corrosive finish minimize wear, reduce noise during rotation, and limit maintenance interventionsresulting in improved operational uptime and reduced life cycle costs for the furnace system.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+