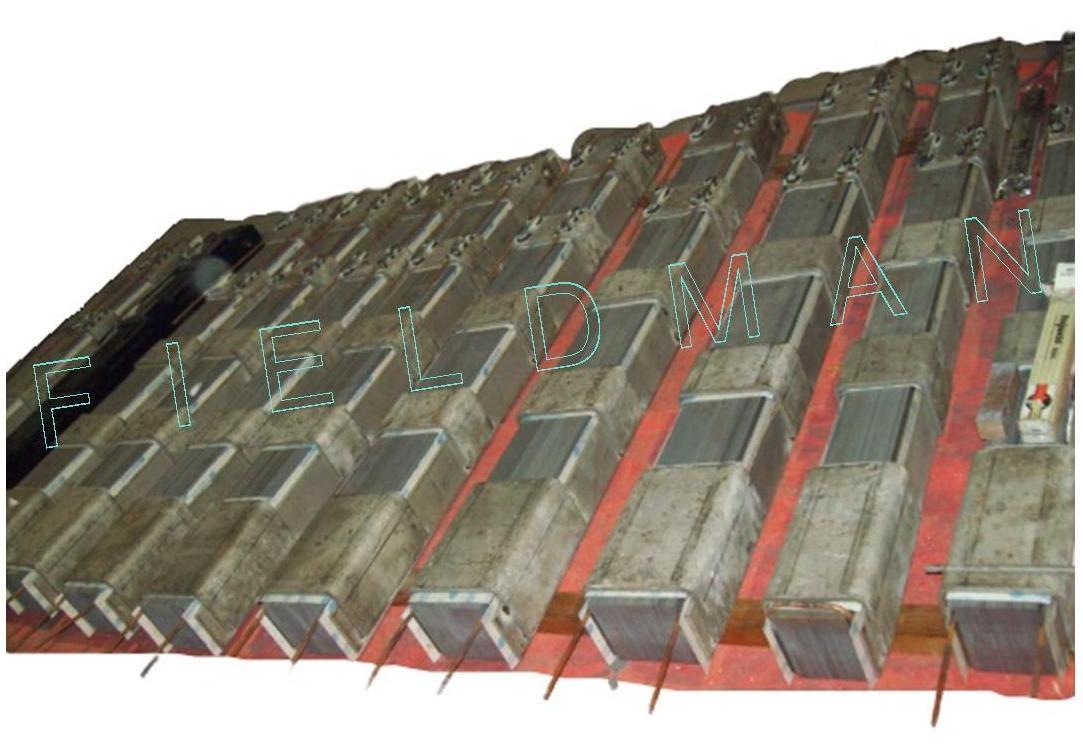

Magnetic Shunt/Yoke

451000 INR/Unit

Product Details:

- Feature High Permeability, Low Loss, Durable Finish, Precision Machined

- Rating Industrial Grade

- Condition New

- Type Magnetic Shunt / Yoke

- Usage Magnetic Circuit Applications, Transformers, Reactors

- Power Not Applicable (Passive Component)

- Size Customizable as per application

- Click to view more

X

Magnetic Shunt/Yoke Price And Quantity

- 1 Unit

- 451000 INR/Unit

- Available

- Up to 150°C or as per material

- Bolt-on/Clamp-on Type

- Natural Metal Finish or Painted

- 2-4 Weeks after Order Confirmation

- Yes

- +/- 0.25 mm or as per drawing

- Smooth, Rust Proof, Industrial Paint

- Anti-Rust Coating or as customer specified

- Export Worthy Wooden Box or as per customer requirement

- Cold Rolled Grain Oriented (CRGO) Steel, Silicon Steel, or Custom Alloys

- Rectangular / U-Shape / As per design

Magnetic Shunt/Yoke Product Specifications

- Industrial Grade

- Varies as per Size and Material

- High Magnetic Flux Handling

- Magnetic Shunt / Yoke

- High Permeability, Low Loss, Durable Finish, Precision Machined

- As per customer specification / drawing

- Magnetics, Power Systems, Electrical Engineering

- Customizable as per application

- Not Applicable (Passive Component)

- New

- Magnetic Circuit Applications, Transformers, Reactors

- Available

- Up to 150°C or as per material

- Bolt-on/Clamp-on Type

- Natural Metal Finish or Painted

- 2-4 Weeks after Order Confirmation

- Yes

- +/- 0.25 mm or as per drawing

- Smooth, Rust Proof, Industrial Paint

- Anti-Rust Coating or as customer specified

- Export Worthy Wooden Box or as per customer requirement

- Cold Rolled Grain Oriented (CRGO) Steel, Silicon Steel, or Custom Alloys

- Rectangular / U-Shape / As per design

Magnetic Shunt/Yoke Trade Information

- Yes

- Western Europe, Eastern Europe, Middle East, Central America, South America, Asia, North America, Australia, Africa

- All India

Product Description

We offer Magnetic Yoke/ shunt for Steel shall induction furnace with highest 15MT capacity of furnace.We are having in-house manufacturing capacity for all induction furnace spare parts.

Versatile Applications and Custom Options

Engineered for use in magnetic circuits, transformers, reactors, and broader electrical engineering sectors, our magnetic shunts/yokes provide robust handling of magnetic flux with minimal loss. We offer fully customizable options regarding dimensions, shape, surface finish, and mounting type to fit every unique application. Every unit is made to customer specifications and packed securely in export-worthy boxes, ensuring safe international delivery.

Superior Material Selection and Finish

Manufactured from CRGO steel, silicon steel, or other custom alloys, our shunts/yokes feature anti-rust or industrial paint finishes. Precision machining and tight tolerances (+/- 0.25 mm or as required) deliver consistent performance and long-lasting service for demanding industrial environments. Each component is designed for easy integration, high durability, and resistance to corrosion and elevated temperatures.

FAQ's of Magnetic Shunt/Yoke:

Q: How are the materials for magnetic shunts/yokes selected?

A: Materials such as Cold Rolled Grain Oriented (CRGO) steel, silicon steel, or custom alloys are chosen based on their high permeability, low core loss, and capacity to handle strong magnetic flux, ensuring optimal performance for applications like transformers and reactors.Q: What surface treatments are available for corrosion protection?

A: We offer anti-rust coatings, smooth rust-proof finishes, and industrial paint options according to customer specifications. These treatments provide strong corrosion resistance, ensuring durability even in harsh industrial settings.Q: When should I use a bolt-on versus a clamp-on mounting design?

A: Bolt-on mounting is ideal for fixed, secure installations, whereas clamp-on designs are recommended when flexibility or easier removal is required. Selection depends on your equipment, space constraints, and service needs.Q: Where can these magnetic shunts/yokes be utilized?

A: They are designed for magnetic circuit applications, including use in transformers, reactors, electrical switchgear, and various power system components, ensuring versatile compatibility across magnetics and electrical engineering industries.Q: What is the standard lead time for production and delivery?

A: The typical lead time ranges from 2 to 4 weeks after order confirmation, depending on specification complexity and order quantity. Export-worthy packaging ensures safe delivery to both domestic and international destinations.Q: How does the customization process work for unique design requirements?

A: Customers can share detailed drawings or specifications. Our engineering team evaluates the requirements and provides tailored solutions-including specific materials, finishes, sizes, and shapes-to perfectly match the end-use application.Q: What are the benefits of using these magnetic shunts/yokes in power systems?

A: Their high magnetic flux handling, precision machining, low energy losses, and robust anti-corrosion finish contribute to reliable performance, longer service life, and efficiency in power systems and electrical engineering applications.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email